YOUR PARTNER FOR NON CONTACT MEASUREMENT ENGINEERING

ASTECH Angewandte Sensortechnik GmbH is the specialist for non-contact measurements in the industry. Our range of products includes sensors for the detection of velocity, length, distance, position, width and color. In addition to our sensors of the VLM, LDM and CROMLAVIEW® series we also produce according to customer’s requirements and for OEM customers. We have gained extensive experiences in the application of optical sensors under difficult ambient conditions and offer a comprehensive portfolio of accessories for our sensors.

Many years of experience in the field of process measurement technology and engineering, combined with special knowledge in development (microcontroller, FPGAs, CCD sensors), provide ASTECH with the best preconditions for innovative engineering.

ASTECH is your partner for problem solving in the field of measurement and automation engineering and for the development of optoelectronic sensors, as well as customized solutions.

PRODUCTS

VLM SERIES

Non-contact measurement of speed and length

VLM500

Non-contact measurement of speed and length

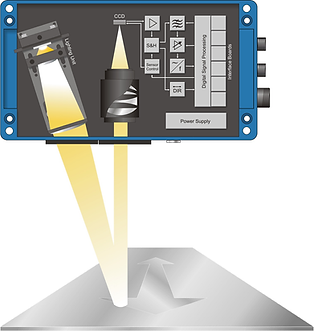

The VLM500 works optically and contact-free. Based on a CCD sensor it implements the spatial filter principle. Spatial filter is the generic term for a measuring principle for the optical determination of velocity and length of moving objects.

The spatial filter is based on the filtering effect of lattice-like structures (grid modulation). Basically, the functional principle of the VLM500 can be described as follows: The measuring object is projected on the CCD sensor which functions as an optical grid (no image taking). The VLM500 is equipped with an LED light source for the illumination of the measuring object. Due to the grid modulation a signal frequency, which is proportional to the speed, occurs upon movement of the object. The device calculates the velocity from the measured signal frequency. Several control circuits allow for automatic adjustment to most diverse materials.

The VLM500 does not put high requirements on the surface character of the measuring object: Precise measurement is facilitated on periodic structures as well as on stochastic surfaces of metals, wood, rubber or paper.

Advantages:

-

Contactless

-

Measuring range up to 50 m/s

-

Measuring uncertainty ±0.025 %

-

Working distances: 185 mm, 240 mm or 330 mm (and customized)

-

Slip-free

-

Wear-free

-

Material independent

-

High power illumination LED

-

No dangerous laser radiation

-

Robust and precise

-

Insensitive to contamination

-

Economical

-

Various interfaces

-

Easy installation

-

Easy maintenance

-

PC software for parameterization

-

60-months warranty

-

Quality product made in Germany

VLM502

Non-contact measurement of speed and length for limited space

The VLM502 works optically and contact-free. Based on a CCD sensor it implements the spatial filter principle. Spatial filter is the generic term for a measuring principle for the optical determination of velocity and length of moving objects.

The spatial filter is based on the filtering effect of lattice-like structures (grid modulation). Basically, the functional principle of the VLM502 can be described as follows: The illuminated measuring object is projected through lenses on the CCD sensor which acts as an optical grid. The VLM502 is equipped with a LED light source for the illumination. Due to the grid modulation a signal frequency, which is proportional to the speed, occurs upon movement of the object. The device calculates the velocity from the measured signal frequency. Several control circuits loops for an automatic adjustment to most diverse materials.

There are rarely requirements on the surface character of the measuring object. Precise measurements are facilitated on periodic structures as well as on stochastic surfaces of metals, wood, rubber or paper.

Advantages:

-

Contactless

-

Measuring range up to 50 m/s

-

Measuring uncertainty ±0.025 %

-

Working distance: 85 mm

-

Slip-free

-

Wear-free

-

Material independent

-

High power illumination LED

-

No dangerous laser radiation

-

Robust and precise

-

Insensitive to contamination

-

Economical

-

Various interfaces

-

Easy installation

-

Easy maintenance

-

PC software for parameterization

-

60-months warranty

-

Quality product made in Germany

VLM60

Compact non-contact measurement of speed and length

The non-contact optical VLM60 is a modern speed and length measuring device in a robust aluminum IP65 housing. An automatically controlled white light LED illuminates the surface of the measuring object. The reflected light is projected onto the optical track image sensor by the integrated precision optics. The movement of the measurement object is recorded in this way by means of a correlation method. The speed is measured bidirectionally in both the x and y directions. The VLM60 can be used as a direct replacement for measuring wheels. The built-in TTL pulse output has two phases A and B for both directions of movement. Optionally, the contactless sensor can be expanded to include an Ethernet-based fieldbus interface. Thanks to the flexible installation position, the small dimensions and the short measuring distance of 100 mm, the VLM60 can be easily integrated into a wide variety of systems.

Advantages:

-

Detection of longitudinal and transverse movement

-

Detection of change of direction

-

No minimum speed, measurement from 0 m/s

-

Working distance: 100 mm

-

Slip-free

-

Wear-free

-

High-Power illumination LED, replaceable

-

No harmful LASER radiation

-

Robust and precise

-

Easy Installation

-

Easy to maintain

-

PC-Software for parameterization

-

Quality product Made in Germany

Robust and versatile

Due to its robust construction, the VLM60 is designed for use in harsh industrial environments. The degree of protection IP65 enables measurements even under adverse measuring conditions. This enables the device to record speeds and lengths in a large number of production processes.

Low service and maintenance costs

Due to the non-contact measuring principle, the VLM60 not only works more precisely than contact rolling systems, but also without friction-related wear. This minimizes the service effort and also prevents damage to or influence on the surface to be measured.

Flexible and integrable

The user can easily and flexibly adapt the output signals to his application thanks to the parameterization. Among other things, acquisition and output times, sliding averaging or the scaling of the pulse output can be parameterized. The VLM60 can also be easily integrated into existing processes, controls or process data acquisition through its optional fieldbus interface. The Windows-PC based "VLMTool" software is available for download free of charge.

LDM SERIES

Distance measurement and position detection

The LDM301A measures distances to targets up to 3000 m away with a precision down to the centimeter. It is able to detect the speed of moving objects with high accuracy. Operated without a reflector, the LDM301A convinces with a range of 300 m on almost each surface.

In addition to the large working range, the LDM301A is characterized by very short measuring times down to 0.1 ms. The compact design of the device, the easy set-up and the standard interfaces RS422 or RS232 allow for easy installation and operation. The status of the device can be monitored via LED display during operation.

The heating integrated in the device ensures reliable operation at temperatures as low as -40°C. The LDM301A offers the option to add a visor or additional interfaces, such as PROFIBUS DP and SSI.

Applications

-

Process monitoring in steel and rolling mills

-

Fill level measurement

-

Monitoring and positioning of cranes and conveying systems

-

Position control

-

Measurements at difficult-to-access measuring points in cavities, tubes, containers and cases

-

Position monitoring of vehicles and vessels

The laser distance measurement sensor LDM302A is technically based on the versatile LDM301A. It has, however, especially been optimized for reliable distance measurements on poorly reflecting surfaces.

The proven time-of-flight measurement principle combines high resistance against ambient interferences with the safety of laser class 1. The high-energy, but very short laser pulses allow for measurements with centimeter precision and a high repetition rate.

The signal processing that has been changed compared against the LDM301A ensures reliable measurements up to 200 m without reflectors with a target reflectivity of only 6%.

The sensor can also be used in harsh industrial environments, such as ports or open cast mines due to the integrated heating and the protective housing according to protection class IP 67. The LDM302A offers the option to add visors or additional interfaces such as Profibus DP.

Applications

-

Positioning of vessels in docking support systems

-

Process monitoring in steel and rolling mills

-

Monitoring of conveying systems

-

Position control in mining

LDM41A and LDM42A - Robust and precise laser distance sensors up to 100 m

LDM41EI and LDM42EI - Laser distance measurement with EtherNet/IP

LDM41P and LDM42P - Precise laser distance measurement for Profibus DP

LDM41PN and LDM42PN - Precise laser distance measurement device with Profinet interface

LDM42E - Network-compatible laser distance sensor

OEM laser module RF42 - Robust and precise OEM laser module - up to 100 m

CROMLAVIEW® SERIES

Perceptive high performance color sensors

CR10

One channel color sensor

Perceptual single-channel color sensor with a large range of functions

Although the CROMLAVIEW® CR10 is located in a very affordable price range, it is equipped with perceptive color recognition and the proven CROMLASTAB® technology. The parameterization of the sensor is very simple and is done by only three times pressing a push button.

Despite the extremely compact construction of 41 mm x 46 mm x 22 mm, the sensor is equipped with a very generous range of functions. In addition to a single sensor button with a LED for indicating the operating conditions, the sensor has two control inputs, which can be used to trigger the measurement and to teach-in a color value. Color values can be stored with five different tolerance values. Furthermore, a teach-in is possible in the multiteach mode, in which the tolerance value is determined solely by the presentation of several color values.

Practically relevant in the industrial environment is the setting of a key lock and the optional setting of an output holding time of 50 ms at the output. Thus, very short color pulses, e.g. in the case of very fast objects can be extended for slow PLCs. The switching output itself (24 V / 200 mA) is short-circuit-proof. A special feature is the detection and display of an output short circuit. To be able to cope with the harsh industrial environment, the sensor electronics is housed in an anodized aluminum housing. This is waterproof so that the IP67 degree of protection can be achieved. Just like the existing CROMLAVIEW® color sensors, the CROMLAVIEW® CR10 also operates perceptively (according to the color perception of the human eye) and processes the color values in the L*a*b* color space. This makes it unique in the category of single-channel color sensors in its market environment.

The functional principle of the CROMLAVIEW® CR10 is based on the three range procedure. The measuring light is assessed with the tristimulus value functions and assigned to the three wave length ranges red, green and blue. Through the assessment with these tristimulus value functions the sensor is able to perceive colors similar to the human eye.

The sensor contains an own white light source clocked with a frequency of 2 kHz. Sampling takes place in both, the light and the dark phase. Additive ambient light cannot change the difference between the light and dark phase, so that the sensor is independent from ambient light.

CR100

Compact and true-color

Industrial Color Sensors with the precision of the human eye

The recognition of finest color differences on surfaces of all kinds is the strength of the CROMLAVIEW® CR100 color sensor. Due to an optical fiber connection the sensor can be adapted to a large number of applications. Thus, the size of the measuring spot and the working distance are variable. Through a sophisticated control concept the sensor can be comfortably be parameterized via buttons. For more complex tasks a PC tool is provided which visualizes all settings and manages the 350 colors that can be stored in the sensor and be exported in a CSV file if required. With a size of (50 × 50 × 21) mm³ the sensor that has been equipped with a powerful LED is very compact. The integrated stabilization channel technology CROMLASTAB® ensures reliable operation during the whole life cycle and protects it from temperature drift as well.

The functional principle of the CR100 is based on the three range procedure. The measuring light is assessed with the tristimulus value functions and assigned to the three wave length ranges red, green and blue. Through the assessment with these tristimulus value functions the sensor is able to perceive colors similar to the human eye. The sensor contains an own white light source clocked with a frequency of up to 10 kHz. Sampling takes place in both, the light and the dark phase. Additive ambient light cannot change the difference between the light and dark phase, so that the sensor is independent from ambient light.

CR100-FO

Compact color sensor with fixed optics

Industrial Color Sensors with the precision of the human eye

Due to its design as a sensor with fixed optic the CROMLAVIEW® CR100-FO color sensor is even more compact the well-known CR100. It recognizes finest color differences on all kinds of surfaces. The working distance lies in a range of 30 - 60 mm, depending on this distance the measuring spot diameter varies between 5 and 10 mm. There are two methods to put the color sensor into operation, via buttons on the sensor, but also by using the free delivered software CR-tool for parameterization.

A mounting bracket is provided for the adjustment of the sensor on the measuring object.

The functional principle of the CR100-FO is based on the three range procedure. The measuring light is assessed with the tristimulus value functions and assigned to the three wave length ranges red, green and blue. Through the assessment with these tristimulus value functions the sensor is able to perceive colors similar to the human eye.

The sensor contains an own white light source clocked with a frequency of up to 10 kHz. Sampling takes place in both, the light and the dark phase. Additive ambient light cannot change the difference between the light and dark phase, so that the sensor is independent from ambient light.

CR100-PM

Fully automatic print mark detection

Fully automatic print mark detection

Automatic detection of print marks makes the CR100-PM an easy-to-use print mark sensor. Due to the perceptive color processing the sensor can recognize print marks with a low contrast to the background. Thanks to the adaptive control system the sensor can adjust its threshold to fluctuating contrast of the print marks. This ensures reliable detection also in applications with difficult ambient conditions. Its independence from ambient light and the integrated stabilization channel technology CROMLASTAB® ensure reliable operation during the whole life cycle.

The functional principle of the CR100-PM is based on the three range procedure. The measuring light is assessed with the tristimulus value functions and assigned to the three wave length ranges red, green and blue. Through the assessment with these tristimulus value functions the sensor is able to perceive colors similar to the human eye.

The sensor contains an own white light source clocked with a frequency of up to 10 kHz. Sampling takes place in both, the light and the dark phase, so that the sensor is independent from ambient light.

The operation of the sensor is comfortable and easy. The user does not have to teach in color marks, as they are automatically recognized and stored by the sensor. After a start signal the sensor scans the background. Deviations are automatically recognized as marks. Corresponding to the number of output channels it is possible to teach in and display 4 different color marks automatically.

CR200 - Differential color detection for highest requirements

CR200E - Differential color detection with Ethernet connectivity

CR200EI - Differential color detection with EtherNet/IP connectivity

CR200P - Differential color detection with Profibus connectivity

CR200PN - Differential color detection with Profinet connectivity

Differential color detection for highest requirements

The CROMLAVIEW® CR200 color sensor processes colors in a perceptual way (i.e. according to human perception). The two channels allow for applications that demand high standards of the sensor technology. By using the second color sensor channel this sensor can be used in different modes of operation.

-

In the dual channel mode the sensor can be operated as two single sensors, which work with the same gain and illumination intensity.

-

With the activated stabilization function (CROMLASTAB®) the sensor can be used with an external stabilization target as a single channel sensor. The symmetric design of the sensor facilitates very high drift stability against age and temperatures.

-

In the color difference mode, compliance and synchronism between the two sensing channels are crucial. The balancing method CROMLABALANCE® is available for this purpose. It allows for simple and effective channel balancing over the client's entire color space. When teaching in a "zero-difference" between the two color channels, test objects can be inspected for color identity, even if the absolute color has not been fixed. A zero-difference can also be used for edge detection. Another advantage of the color difference mode is the recognition of transparent objects against changing backgrounds (e.g. transparent labels in the packaging industry). Changing backgrounds can frequently occur in terms of deviations in height or structure of the object. Also in such cases, the color difference mode facilitates the recognition of colored structures, which would otherwise be impossible with an absolute measurement.

CR210 - The color sensor processes colors in a perceptual way

CR210E - Perceptive color processing with Ethernet connectivity

CR210EI - Perceptive Color Processing with EtherNet/IP connectivity

CR210P - Perceptive color processing with Profibus connectivity

CR210PN - Perceptive color processing with Profinet connectivity

The color sensor processes colors in a perceptual way

The CROMLAVIEW® CR210 color sensor processes colors in a perceptual way (i.e. according to human perception) and assesses color distances with the precision of the human eye. For this purpose, a Lab color space is used in the color sensor, which has been equipped with a 4 Watt high power white light LED. Color distances are measured and assessed the same way humans would do. This sensor offers a maximum of flexibility, as it can be combined with a large number of optical fibers and focus optics by means of an optical fiber connection. On the other hand, multiple interfaces leave nothing to be desired. The color sensor, for example, can be connected with the computer via RS232 or USB interfaces. The free software CR-Tool, supplied with all CROMLAVIEW® color sensors, facilitates the parameterization and the visualization of color values. Besides that, the color sensor can also be operated using the buttons. More standard interfaces are 12 push-pull switching lines (24 V/100 mA per line), which, when binary encoded, can output 4096 switching states. As all the other CROMLAVIEW® color sensors, the CR210 is also equipped with the CROMLASTAB® technology, which protects it from temperature and age drift and thus ensures secure and reliable operation in the whole life cycle.

The functional principle of the CR210 is based on the three range procedure. The measuring light is assessed with the tristimulus value functions and assigned to the three wave length ranges red, green and blue. Through the assessment with these tristimulus value functions the sensor is able to perceive colors similar to the human eye.

The sensor contains an own white light source clocked with a frequency of up to 10 kHz. Sampling takes place in both, the light and the dark phase. Additive ambient light cannot change the difference between the light and dark phase, so that the sensor is independent from ambient light.

CR50

Compact color sensor - intuitive controllable

Perceptive color sensor with intuitive control concept

The recognition of finest color differences on surfaces of all kinds is the strength of the CROMLAVIEW® CR50 color sensor. Due to an optical fiber connection the sensor can be adjusted to a large number of applications. Thus, the size of the measuring spot and the measuring distance are variable. Through a sophisticated control concept the sensor can be comfortably be parameterized via buttons. With a size of (50 × 50 × 21) mm3 the sensor that has been equipped with a powerful LED is very compact. The integrated stabilization channel technology CROMLASTAB® ensures reliable operation during the whole life cycle and protects it from temperature drift as well.

The functional principle of the CR50 is based on the three range procedure. The measuring light is assessed with the tristimulus value functions and assigned to the three wave length ranges red, green and blue. Through the assessment with these tristimulus value functions the sensor is able to perceive colors similar to the human eye.

The sensor contains an own white light source clocked with a frequency of up to 2 kHz. Sampling takes place in both, the light and the dark phase. Additive ambient light cannot change the difference between the light and dark phase, so that the sensor is independent from ambient light.

CR50-FO

Compact color sensor with fixed optics

Perceptive color sensor with fixed optics and intuitive control concept

Due to its make as a color sensor with fixed optics the CROMLAVIEW® CR50-FO color sensor is very compact. The sensor recognizes finest color differences on all kinds of surfaces. The working distance lies in a range of 30 - 60 mm, depending on this distance the diameter of the measuring spot varies between 5 and 10 mm. The sensor can easily be programmed using the intuitive and simple button operation.

A mounting bracket is provided for the alignment of the sensor on the measuring object.

The functional principle of the CR50-FO is based on the three range procedure. The measuring light is assessed with the tristimulus value functions and assigned to the three wave length ranges red, green and blue. Through the assessment with these tristimulus value functions the sensor is able to perceive colors similar to the human eye.

The sensor contains an own white light source clocked with a frequency of up to 2 kHz. Sampling takes place in both, the light and the dark phase. Additive ambient light cannot change the difference between the light and dark phase, so that the sensor is independent from ambient light.

MEASURED VARIABLES

Non-contact measurement with light

Acceleration (VLM)

Description: The measuring device VLM records the surface velocity of the measuring object optically and contact-free from the distance. This takes place independently from its color, brightness or surface structure. Due to the measuring principle the device works slip-free and records high accelerations, too.

Applications: Velocity measurement, Length measurement (Tube inspection lines)

Products: VLM500, VLM500-MID, VLM502, VLM60

Color (CR)

Description: CROMLAVIEW color sensors are based on the three-range procedure and they process colors according to human perception. Color-sensitive filters, which emulate the tristimulus function of the human eye, facilitate the correct recognition of color values. In terms of color information, opaque solid objects can be evaluated in the epi-illumination method, transparent liquids in the transmitted light method and self-luminous objects in the active mode.

Applications: Abrasion measurement (Research and Development), Coating inspection (Quality assurance), Coating inspection (Quality assurance), Coating inspection of foam material (Conveyor belt), Color inspection (Final assembly), Color inspection (Final assembly), Color inspection (Quality assurance), Color mark detection (Tube inspection lines), Color measurement of salmon meat (Conveyor belt), Egg yolk color classification (Laboratory), PET preform inspection (Filling plant)

Products: CR10, CR100, CR100-FO, CR200, CR200E, CR200EI, CR200P, CR200PN, CR210, CR210E, CR210EI, CR210P, CR210PN, CR500

Degree of stretching and Skin pass level (VLM)

Description: The measuring device VLM records the surface velocity of the measuring object optically and contact-free from the distance. This takes place independently from its color, brightness or surface structure. The measuring principle of the device allows for slip-free operation and records high accelerations, too. Due to the high precision of measurements several sensors can be used to detect slight differential velocity, such as the degree of stretching and skin pass level.

Applications: Velocity measurement (Skin pass level, degree of stretching, mass flow)

Products: VLM500, VLM502

Diameter (LDM)

Description: Broad objects can be geometrically measured with the laser distance sensors of the LDM series. In order to measure the diameter of a roll, only the distance to the axis needs to be known. Via the programmable offset and the scaling factor the measuring device is parameterized in a way that the diameter is directly output.

Applications:

Products: LDM301A, LDM302A, LDM41A and LDM42A, LDM41P and LDM42P, LDM41PN and LDM42PN, LDS30A, OEM laser module LDS30M, OEM laser module RF42

Distance (LDM)

Description: By means of laser radiation and special measuring procedures the laser distance sensors of the LDM series are capable of measuring the distance between themselves and almost any natural surface. Depending on the deployed type they can reach distances of up to 300 m with a precision down to the millimetre and achieve measuring frequencies of up to 30 kHz. The devices of the LDM series use harmless laser radiation in the visible (red, 650nm, laser class 2) or invisible (infrared, 935nm, laser class 1) range of the spectrum.

Applications: Collision avoidance (Gantry cranes), Distance measurement (Ports, docking systems), Position detection (Engineering)

Products: LDM301A, LDM302A, LDM41A and LDM42A, LDM41P and LDM42P, LDM41PN and LDM42PN, LDM42E, LDS30A, LDS70A, OEM laser module LDS30M, OEM laser module RF42, RF70A

Fill level (LDM)

Description: The detection of the fill level of solid materials in silos can easily be realised with the devices of the LDM series. Mounted at the top of the silo the distance sensor measures the distance to the angle of repose of the poured-in material permanently. Signaling of the fill level is executed via the freely-programmable analog output. At the same time, reaching the limit values "Full" and "Empty" can be realised via the digital switching outputs which can also be adjusted.

Applications: Fill level measurement (Bulk solid silo), Fill level measurement (Cement storage)

Products: LDM301A, LDM302A, LDM41A and LDM42A, LDM41P and LDM42P, LDM41PN and LDM42PN, LDM42E, LDS10A, LDS30A, LDS70A, OEM laser module LDS30M, OEM laser module RF42, RF70A

Impact energy (VLM)

Description: The measuring device VLM records the surface velocity of the measuring object optically and contact-free from the distance. This takes place independently from its color, brightness or surface structure. The measuring principle of the device allows for slip-free operation and records high accelerations, too. The mass and velocity of an object are used to determine its kinetic energy.

Applications: Measurement of impact energy (Forge hammer)

Products: VLM500, VLM502

Length (LDM)

Description: Broad objects can be geometrically measured with the laser distance sensors of the LDM series. Usually two devices are arranged opposed to one another, thus determining the distance to the measuring object between them. From the measured distances and the previously known distance between the sensors it is possible to calculate variables such as length, width, thickness or diameter. This is mainly executed in a superior control or calculator units. Widths, lengths and thicknesses can then be used for calculating volume or surface.

Applications: Length measurement (Steel billets)

Products: LDM301A, LDM302A, LDM41A and LDM42A, LDM41P and LDM42P, LDM41PN and LDM42PN, LDS30A, OEM laser module LDS30M, OEM laser module RF42

Length (VLM)

Description: The measuring device VLM records the surface velocity of the measuring object optically and contact-free from the distance. This takes place independently from its color, brightness or surface structure. Due to the measuring principle the device works slip-free and records high accelerations, too. The length of the object is calculated from the measured object velocity and the measuring time. It is possible to determine endless lengths and the length of individual objects.

Applications: Control of shears (Finishing, Slitting line, Winder), Control of shears (Extruder), Length measurement (Coil lines, Inspection lines), Length measurement (Quality assurance), Length measurement (Coiling machines), Length measurement (Finishing, Slitting lines), Mobile velocity and length measurement (Service, Commissioning, Research), Velocity measurement, Length measurement (Tube inspection lines), Velocity measurement, Length measurement (Hot objects)

Products: VLM500, VLM500-MID, VLM502, VLM60

Position (CR)

Description: The position of print marks and printed images is detected by using CROMLAVIEW high velocity color sensors in the sub millimeter range with high track speeds. They can for example be used for register controls.

Applications: Coating inspection (Quality assurance), Presence check (Filling plant), Print mark detection (Printing machine, banderoling machine, register control)

Products: CR10, CR100, CR100-FO, CR100-PM, CR200, CR200E, CR200EI, CR200P, CR200PN, CR50, CR50-FO, CR500

Position (LDM)

Description: Measuring devices of the LDM series can be used for the detection of the position of large objects, such as machines or vehicles. They can measure the distance between themselves and almost any natural surface contactless. The programmable offset of the distance measurement can then be used to shift the zero point and to indicate the vertical movement directly. Parameterization with an appropriate scaling factor facilitates direct output in a predetermined unit (m, feet, yards)

Applications: Position detection (Coil storage), Position detection (Engineering), Positioning of containers in gantry cranes (Container ports)

Products: LDM301A, LDM302A, LDM41A and LDM42A, LDM41P and LDM42P, LDM41PN and LDM42PN, LDM42E, LDS30A, LDS70A, OEM laser module LDS30M, OEM laser module RF42, RF70A

Position (VLM)

Description: The measuring device VLM records the surface velocity of the measuring object optically and contact-free from the distance. The length of the object is calculated from the measured object velocity and the measuring time. This facilitates the determination of the position of a passing object.

Applications:

Products:

Position detection (CR)

Description: The position of an object with different surfaces can be detected with a dual-channel differential color sensor. The position can be detected on the basis of the sign of the color difference between the two surfaces of the object.

Applications: Coating inspection of foam material (Conveyor belt)

Products: CR200, CR200E, CR200EI, CR200P, CR200PN

Presence (CR)

Description: The presence and the correct position of assembly parts can often be assessed by the resulting color effect, as it usually depends on the distance and the angle.

Applications: Coating inspection (Quality assurance), Presence check (Filling plant), Presence check (Decapper)

Products: CR10, CR100, CR100-FO, CR200, CR200E, CR200EI, CR200P, CR200PN, CR210, CR210E, CR210EI, CR210P, CR210PN, CR50, CR50-FO, CR500

Presence (LDM)

Description: The LDMs use the measured distance to detect the presence of an object within a specific, programmable measuring range independently. All laser distance sensor have one or two freely-programmable digital switching outputs to signal the results.

Applications: Presence check (Railway, Transportation)

Products: LDM301A, LDM302A, LDM41A and LDM42A, LDM41P and LDM42P, LDM41PN and LDM42PN, LDS10A, LDS30A, LDS70A, OEM laser module LDS30M, OEM laser module RF42, RF70A

Quantity (CR)

Description: Color marks and colored objects can be detected by using a color sensor. The industry-suitable evaluation modules determine the quantity and can use multipliers to convert it, for example, into a length. ASTECH offers the complete one-source system.

Applications: Sandwich counter (Packing)

Products: CR10, CR100, CR50

Thickness (LDM)

Description: If several laser distance sensors are appropriately arranged above and below the material, the recorded distance values can be used to determine the thickness profile of strip material. In such cases, the use of devices with a PROFIBUS interface is especially convenient, as all devices can easily be connected with a superior control, where the thickness profile is calculated by using the measured distance values and the known positions of the measuring devices.

Applications: Multiple

Products: LDM301A, LDM302A, LDM41A and LDM42A, LDM41P and LDM42P, LDM41PN and LDM42PN, LDS30A, OEM laser module LDS30M, OEM laser module RF42

Velocity (VLM)

Description: The measuring device VLM records the surface velocity of the measuring object optically and contact-free from the distance. This takes place independently from its color, brightness or surface structure. Due to the measuring principle the device works slip-free and records high accelerations, too.

Applications: Control of shears (Extruder), Control of shears (Slitting shears), Mobile velocity and length measurement (Service, Commissioning, Research), Velocity Measurement (Flying saw), Velocity measurement (Skin pass level, degree of stretching, mass flow), Velocity measurement, Length measurement (Tube inspection lines), Velocity measurement, Length measurement (Hot objects)

Products: VLM500, VLM500-MID, VLM502, VLM60

Velocity 1 (LDM)

Description: With the laser distance sensor LDM301A a special measuring modus is available, in which the velocity of the measured objects is calculated based on the change of the recorded distance values.

Applications: Distance measurement (Ports, docking systems)

Products: LDM301A, LDM302A, LDS70A, RF70A

Velocity 2 (LDM)

Description: With the PC software LDMSpeed the laser distance sensor LDM41A can be used for the measurement of the velocity of individual objects. The ability to measure extremely slow movements contactless is especially advantageous.

Applications: Distance measurement (Ports, docking systems)

Products: LDM301A, LDM302A, LDM41A and LDM42A, LDM41P and LDM42P, LDM41PN and LDM42PN, LDS70A, OEM laser module RF42, RF70A

Width (LDM)

Description: Broad objects can be geometrically measured with the laser distance sensors of the LDM series. Mostly, two devices are arranged opposed to one another, thus determining the distance to the measuring object between them. From the measured distances and the known distance between the sensors it is possible to calculate variables such as length, width, thickness or diameter. This is mainly executed in a superior control or calculator units. Widths, lengths and thicknesses can then be used for calculating volume or surface.

Applications: Position detection (Coil storage)

Products: LDM301A, LDM302A, LDM41A and LDM42A, LDM41P and LDM42P, LDM41PN and LDM42PN, LDM42E, LDS30A, LDS70A, OEM laser module LDS30M, OEM laser module RF42, RF70A